Discover the Incredible Power of Snatch Blocks:

Professionals in industries ranging from construction to off-road vehicle recovery understand the crucial role that snatch blocks play in their day-to-day operations. In this guide, we'll explore various snatch blocks, their uses, and key points to consider when choosing, using, and maintaining them.

What Exactly Are Snatch Blocks?

Snatch blocks significantly increase the efficiency

and versatility of lifting and pulling tasks

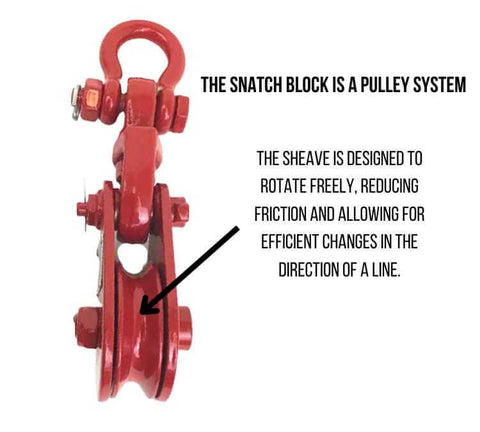

To truly understand the value of snatch blocks, also known as rigging blocks, we first need to grasp what they fundamentally are. A snatch block is a simple yet effective pulley system that consists of a sheave mounted between steel frames. The sheave is designed to rotate freely, reducing friction and allowing for efficient changes in the direction of a line.

Whether you're a construction expert managing large-scale projects or a vehicle transport towing operator navigating the tough terrains, snatch blocks are an instrumental ally. Their ability to transform force direction and intensity means that they're more than just a piece of equipment!

There are various snatch blocks designed for specific tasks.

Common types are fixed and swivel. Fixed blocks remain in set positions, perfect for straightforward lifting. Swivel blocks, on the other hand, allow more movement and flexibility, ideal for situations where the pull direction frequently changes.

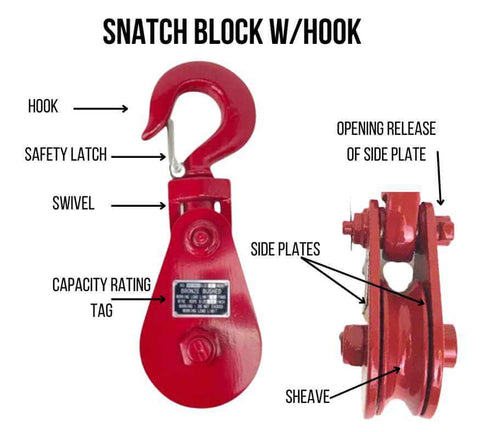

Snatch Blocks with Swivel Hook: Typically used with wire rope hoists and winches for short-term tasks. Can be used with wire rope, such as winch cables, and rope.

Snatch Blocks with Shackle: Unlike snatch blocks with a swivel hook, which are predominately used for temporary lifting and pulling applications, snatch blocks with a shackle offer a more permanent and robust attachment option. This makes them exceptionally suited for heavy-duty lifting, where stability and security are paramount.

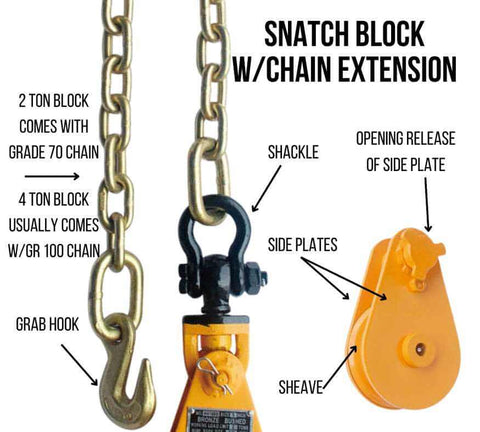

Snatch Blocks with Chain Ends: Its unique feature, a chain extension ending in a grab hook, allows it to easily attach to a wide variety of anchoring points, This helps operators in controlling the distance of the pulls and facilitates the redirection of the load's path.

Whether you're a construction expert managing large-scale projects or a vehicle transport towing operator navigating the tough terrains, snatch blocks are an instrumental ally. Their ability to transform force direction and intensity means that they're more than just a piece of equipment!

Snatch Blocks in Lifting and Pulling

In lifting applications, snatch blocks are often used in conjunction with cranes, hoists, and winches. By changing the direction of the pulling force, they can increase the amount of weight that a winch or line can lift. When used for pulling, snatch blocks allow for pulling a load using a winch at an angle to the load. This can not only double the winch's capacity by halving the load on the cable but also enables more controlled maneuvers, critical in off-road recoveries, roadside assistance towing or tight lifting spaces.

The Advantages of Snatch Blocks

Incorporating snatch blocks enhances safety, efficiency, and effectiveness, making a significant difference.

Safety and Load Control

One of the most significant advantages is the enhanced safety available through the use of snatch blocks. By offering a means to double the load's line, operators can significantly reduce the stress on the line, and by extension, minimize the risk of snaps or breaks. This keeps the gear safe from harm and also looks out for the people working around it.

Increase in Lifting and Pulling Capacity

In situations where the pulling force required exceeds the limit of a winch or cable, snatch blocks step in and effectively double the capacity. When used properly, they can mean the difference between successfully completing a lift or pull or falling short due to capacity constraints.

Versatility in Diverse Applications

Snatch blocks are really useful because they can change the direction and strength of a force when lifting or pulling, making them very versatile in different operations.

Snatch Blocks industries:

The construction industry uses snatch blocks for heavy lifting and load-bearing tasks. Roads, bridges, and skyscrapers are built using cranes and winches, with snatch blocks enhancing safety and efficiency. They allow for more precise control over loads and can even help navigate tight spaces on job sites.

In lifting operations, such as raising steel beams or positioning concrete blocks, snatch blocks are invaluable. They help manage the considerable weights involved, distribute the load across numerous points, and enable precision adjustments with utmost control.

Snatch Blocks in Off-Road Recovery

Off-road vehicles can get stuck in challenging terrain, requiring the use of snatch blocks to safely pull them out. Snatch blocks increase pulling capacity and enable different angles of pulling, making them essential tools for off-road recovery operations.

Snatch Blocks in Towing & Recovery

In vehicle towing and recovery, snatch blocks are pivotal for safe and effective retrieval operations. By enabling winches to exert force from varying angles, snatch blocks can straighten the path for a stuck vehicle or handle awkward angles without overloading the winch or winching point.

They provide the ability to pull from a direction that might not be directly in line with the stuck vehicle, minimizing the risk of roll-overs and damage to the winching gear.

When moving heavy vehicles, trucks, or equipment, snatch blocks help distribute the weight evenly across several winching points. This ensures balanced load bearing and prevents any single point from being overloaded, reducing the risk of failure. They are also used in combination with other tools like shackles, ropes, and chains to create a powerful rigging system.

Choosing the Right Snatch Block for Your Needs

The market offers a variety of snatch blocks suited to different weight capacities, materials, and mechanisms. It's important to select the appropriate type to match the intended use and conditions.

Weight Rating

When picking out snatch blocks, the weight rating is super important. You've got to make sure it can handle the heaviest load you plan on dealing with. Always go for a snatch block that can take on more weight than you think you'll need. This way, you've got a safety net and you won't stress out the equipment.

Material Composition

The durability and performance of a snatch block depend on its material. For lasting use, especially outdoors or in marine settings, stainless steel or similar corrosion-resistant metals are best. For standard towing needs on rollbacks and tow trucks a steel snatch block is good. If you need something lighter, aluminum snatch blocks are a good choice as they're still strong but weigh less.

Type and Mechanism

Selecting between fixed and swivel snatch blocks depends on the level of mobility required for the application.

Proper Maintenance and Caring for your Snatch Blocks

The lifespan and effectiveness of snatch blocks really depend on how regularly they're maintained and how well they're taken care of.

-

Always Check the Load Rating: Before using a snatch block, ensure it’s suitable for the load. Overloading a snatch block can lead to catastrophic failures, endangering lives and damaging property.

-

Inspect Before Use: A thorough inspection of the snatch block for wear, damage, or deformation should be conducted before each use. This includes checking the sheave, pin, and side plates.

-

Use Proper Rigging Techniques: Incorrect rigging can lead to unequal load distribution or slippage, resulting in accidents. Always follow best practices in rigging to ensure a safe and efficient operation.

-

Wear Protective Gear: Safety gloves, goggles, and other protective equipment should be worn by all personnel involved in operations involving snatch blocks to protect against potential injuries.

-

Keep Clear of the Load Path: Never stand in the direct path of a load being lifted or pulled. A failure in the rigging hardware can cause the load to drop or swing unpredictably.

-

Use with Compatible Equipment: Ensure that the snatch block is compatible with the rope or cable being used. Mismatched equipment can lead to inefficient operation or damage to the components.

A Parting word on Snatch Blocks

Snatch blocks serve as an invaluable tool across various industries, offering a multitude of benefits that enhance operational efficiency, safety, and versatility. Their ability to redirect and multiply force adds a layer of versatility, enabling them to be used in diverse applications such as construction, marine, off-road recovery, and vehicle towing.

All gear should be thoroughly inspected before each and every use. Worn or unsafe rigging and safety gear should never be used. Inspect chain slings regularly and to keep a record of all chain inspections. Products should be used in strict accordance with all industry and OSHA standards.